Basic Dimensional Report

This is the straight forward measurement of a component to see if key dimensions are within the required tolerance, or it may help to create a ‘master’ against which future components will be compared. If components are measured in multiples, this can form a CAP (Capability) Study.

There are two types of measurement equipment used –

Contact Measurement:

Measuring components accurately with state of the art CMM Inspection Software means we are capable of accurately measuring down to 1µ.

We get accurate and repeatable dimensional results each and every time through our CNC CMM’s contact probe system.

Our CNC CMM proves itself to be the optimal tool of choice for measurement of a wide variety and size of components through it’s working envelope of 500mm x 700mm x 400mm.

Being able to upload CAD Models onto the system, enables the parts to be aligned to the respective CAD models – allowing for accurate geometry results of any component to the nominal CAD models.

With a large selection of contact probes and extensions at our disposal, LVS QMS has access to an enormous range of configurations that can allow dimensional inspection of even highly complex components.

LVS GMS has access to an extremely large range of configurations which allow dimensional inspection of highly complex components, through a large variety of contacts and probes being at our disposal.

Combining this with our current selection of manual inspection equipment and us here at LVS GMS have the complete set up for all of your metrology and contact measurement needs.

Non-Contact Measurement:

Having access to a full HD Vision System for use on all non-contact measurement requirements allows us here at LVS QMS Ltd to measure down to 1µ. This is achieved through its built-in software enabling measurements to be taken without touching the components. It first captures the image, prior to the software then being used to measure:

• Length

• Diameters

• Radius

• Angle

• Visual Aspects (surface marking, pitting, scratches, flash etc.)

These images are saved as .PNG or .JPEG files with the capability of having dimensional information superimposed directly on to them.

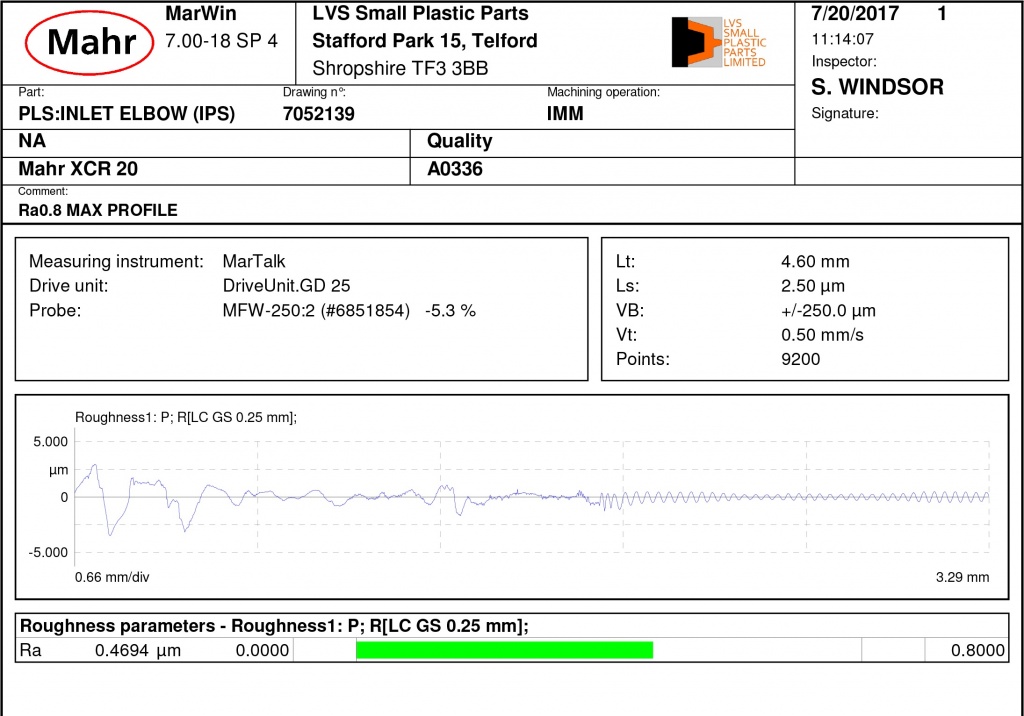

Surface Condition Report

This type of report is used to demonstrate the variations in the surface of a component, in effect, how ‘rough it is’. This is not only relevant to the cosmetic appearance of a product, it is critical if two mating surfaces need to be within a set tolerance. For example, if a rubber ‘O’ Ring has to seat within a groove, surface condition can have a significant impact on both fluid retention and abrasion of the sealing surface.

Fixture Verification

Fixtures are frequently used in production environments, this to quickly check if a component or assembly of components are within tolerance. It is therefore critical that the fixture itself is accurately measured. Below is a typical Fixture Verification Report